Exploring the Advantages of Partnering with China Prototype Mold Manufacturers

In today's globalized economy, businesses are constantly seeking ways to optimize their production processes and reduce costs while maintaining quality. One of the most significant innovations in manufacturing and production is the use of prototypes and molds. With the rise of competitive industries, China prototype mold manufacturers have emerged as go-to partners for companies around the world. Let's delve into the world of prototype manufacturing, highlighting key advantages and essential considerations when working with Chinese manufacturers.

Understanding Prototype Mold Manufacturing

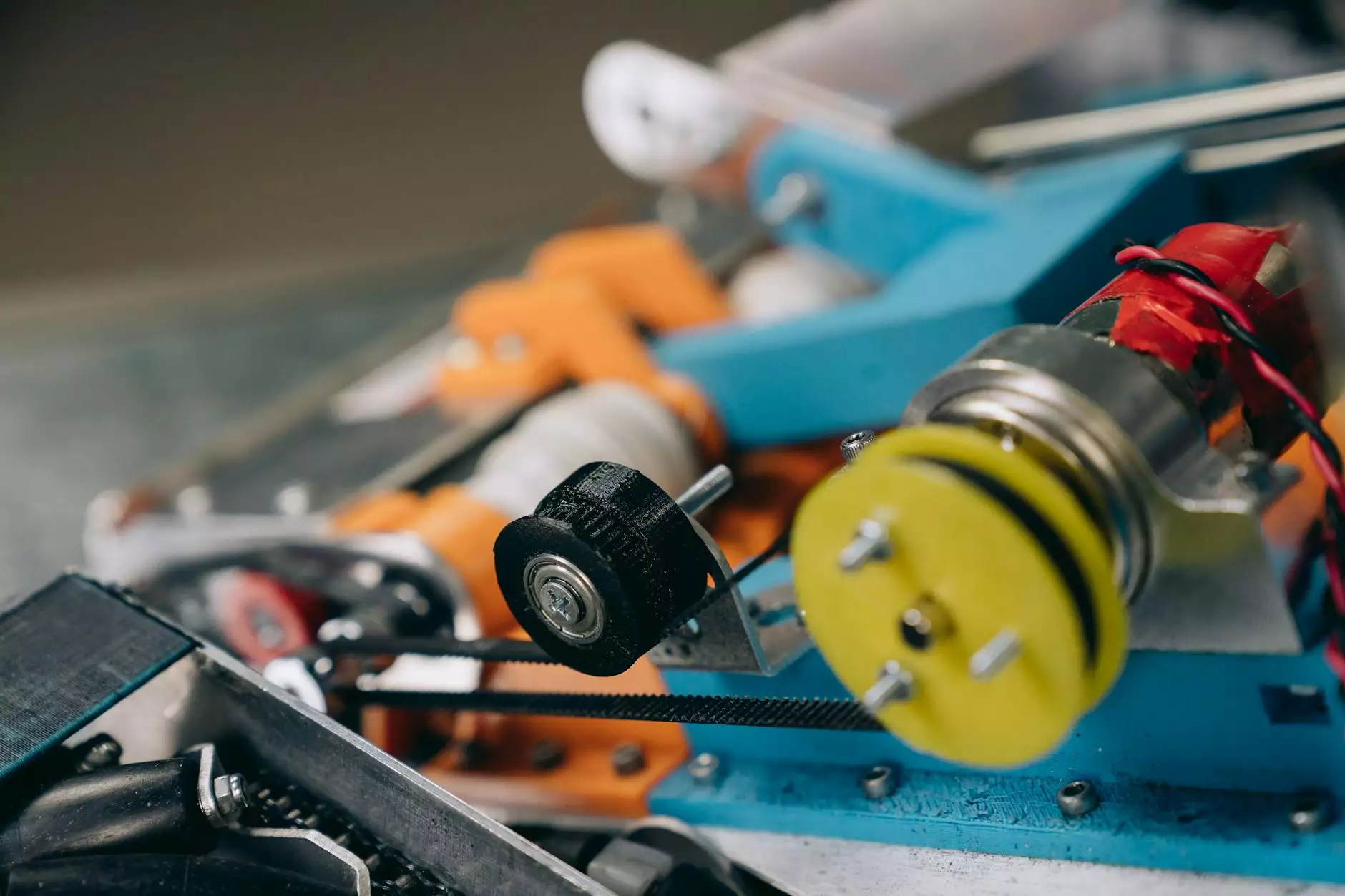

Prototype mold manufacturing is the process of creating a model that will serve as a template for mass production. The molds are essential for producing parts and products consistently and efficiently. Whether you’re in automotive, consumer goods, electronics, or any other industry, having a reliable prototype provider is critical.

What Sets China Prototype Mold Manufacturers Apart?

China has established itself as a leadership hub for manufacturing across various sectors. The reasons behind this dominance include:

- Cost Efficiency: Because of lower labor costs and economies of scale, businesses can save significantly when outsourcing mold production to China.

- Rapid Turnaround Times: Many Chinese manufacturers leverage advanced technologies, enabling quick production without sacrificing quality.

- Diverse Expertise: China hosts hundreds of factories, each specializing in different materials and techniques, offering a vast range of capabilities.

- Quality Assurance: Many manufacturers conform to international quality standards, ensuring that products meet stringent specifications.

- Innovative Technologies: Continuous investments in research and development allow Chinese manufacturers to adopt the latest technologies and manufacturing processes.

The Process of Working with China Prototype Mold Manufacturers

Understanding the workflow involved when partnering with a Chinese manufacturer is crucial for establishing a successful relationship. Below is a step-by-step guide on how to collaborate effectively:

1. Defining Your Project Requirements

Before engaging with a manufacturer, it is essential to have a clear understanding of your requirements including:

- Product specifications

- Material choices

- Desired production timelines

- Budget constraints

2. Researching Potential Manufacturers

Finding the right China prototype mold manufacturers involves exploring various companies and assessing their capabilities. Consider factors such as:

- Reputation and experience

- Previous projects and case studies

- Client testimonials and reviews

- CERTIFICATIONS (e.g., ISO standards)

3. Requesting Quotes and Proposals

Once you have shortlisted potential manufacturers, reach out for quotes. Be specific about your needs to ensure accurate pricing. Compare the proposals, taking into consideration not just the cost, but also the value offered in terms of quality and service.

4. Prototyping and Testing

One of the most critical phases in the process is prototyping. Manufacturers will create initial molds that help in testing the product. Utilize this phase to:

- Gather feedback from stakeholders

- Perform necessary adjustments before mass production

- Evaluate the quality and functionality of the prototype

5. Final Approval and Production

After refining the prototype and gaining stakeholder approval, production can commence. Maintain regular communication with the manufacturer to ensure that:

- The production timeline is adhered to

- Quality controls are implemented

- Any arising issues are addressed promptly

Quality Management in Prototype Mold Manufacturing

Quality management is critical when dealing with China prototype mold manufacturers. Effective quality assurance processes help in maintaining standards throughout the production cycle.

Implementing Quality Standards

Before starting production, ensure that the manufacturer adheres to predefined quality standards. These may include:

- ISO 9001 for Quality Management Systems

- ISO 13485 for Medical Devices

- ISO/TS 16949 for Automotive Industries

Regular Inspections and Assessments

It is vital to conduct regular inspections during the manufacturing process. This can help you identify and address potential issues early, ensuring that final products meet your company’s standards.

Cost Considerations in Partnering with Chinese Manufacturers

Cost is often a significant factor when selecting a manufacturing partner. Here are some critical points to consider:

1. Hidden Costs

While the initial quotes may seem appealing, be wary of hidden costs such as shipping, taxes, and duties. Always calculate the total cost of sourcing from overseas.

2. Pricing Structure

Understanding the pricing structure offered by China prototype mold manufacturers is essential. Manufacturers may offer different payment terms, discounts for bulk orders, or additional services that can impact overall costs.

3. Long-term Savings

Investing in high-quality molds can save money long-term by reducing maintenance needs and ensuring consistent product quality. Therefore, choose wisely based on total cost rather than just initial pricing.

The Future of Prototype Mold Manufacturing in China

The landscape of prototype mold manufacturing in China is continually evolving, with trends focusing on sustainability and innovation:

Innovative Technologies Reshaping the Industry

Advancements in technologies, such as 3D printing and automation, are transforming how molds are designed and produced. These innovations lead to lower costs, improved efficiency, and reduced waste. Furthermore, employing technology in production enables rapid prototyping and shorter lead times.

Sustainable Manufacturing Practices

As global awareness of environmental issues increases, many manufacturers are adopting sustainable practices. This includes:

- Utilizing eco-friendly materials

- Implementing waste reduction techniques

- Investing in energy-efficient machinery

By prioritizing sustainability, China prototype mold manufacturers can help your business meet environmental standards and appeal to eco-conscious customers.

Conclusion: Your Path to Successful Manufacturing with Chinese Partners

In summary, partnering with China prototype mold manufacturers can significantly enhance your business's manufacturing capabilities. The benefits of cost efficiency, rapid turnaround, and access to innovative technologies create a competitive advantage for companies looking to thrive in today's fast-paced market.

By carefully selecting your manufacturing partner and embracing effective quality management, you can ensure that your products meet the highest standards and fulfill your business's objectives. Whether you're looking to produce a few prototypes or scale up to mass production, China can be the ideal partner for your mold manufacturing needs.

For businesses ready to explore these opportunities, consider reaching out to DeepMould, a leading name among China prototype mold manufacturers, to get started on your journey towards efficient and cost-effective manufacturing.